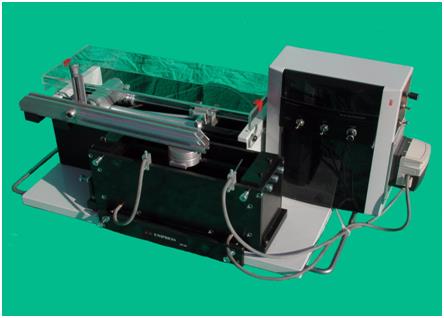

The MS-80 Saw is a precision device for cutting or slicing hard and brittle materials, such as metals, ferrites, ceramics, stones etc. In particular it is useful for cutting semiconducting materials. Saw enables cutting of very thin slices (thicknes of 50 mm) with smooth cut surfaces. This saw is recommended for cutting materials where losses of material should be minimized and cutting should not introduce crystal deformations or defects. Use of special accessories (goniometers, orientation devices) extends MS-80 saw's application im precision cutting of crystallographically oriented crystals.

MS-80 PRECISION RECIPROCATING MULTI BAND SAW

Technical data:

Sample max. dimensions:

Blades

working length:

width:

thickness:

thickness tolerance:

flatness:

tensile strength:

steel grade:

Slurry pump flow rate:

Power supply:

.

Reciprocating motion frequency:

Weight:

Dimensions:

Sample max. dimensions:

Blades

working length:

width:

thickness:

thickness tolerance:

flatness:

tensile strength:

steel grade:

Slurry pump flow rate:

Power supply:

.

Reciprocating motion frequency:

Weight:

Dimensions:

appr. 100 x 100 mm

220 mm

10 mm

0,1 mm

±0,007 mm

0,3% across the width

1960 N/mm2

C 1,00%, Si 0,30%, Mn 0,70%, Cr 0,35%

5,0¸50 ml/min

220-250 V/50 Hz

or 110 V/60 Hz

0¸400 /min

68 kg

600x480x320 mm

Application:

The cutting operation is performed by steel bands (blades) covered with an oil or glicerin-suspended carborundum or boron carbide abrasive slurry pumped in closed loop. The specimen moves back and forth in a reciprocating motion and is cut across in vertical plane by cutting bands. Bands are tightened between two side walls of the tank. Special spacers makes all tapes equidistant and anables cutting of several samples of the same thicknes. It is possible to use different sizes of the spacers to cut several dimensions of the samples in the same time. We might deliver our saws with tensioned bands and set gaps.

General Characteristics:

K.D. UNIPRESS

Providing laboratory equipment since 1990

High Pressure Physics Institute

Polish Academy of Science