appr. 40 x 40 mm

220-250 V/50 Hz

or 110 V/60 Hz

20-60 µm

100-300 µm

150-200 /min

48 kg

600x500x250 mm

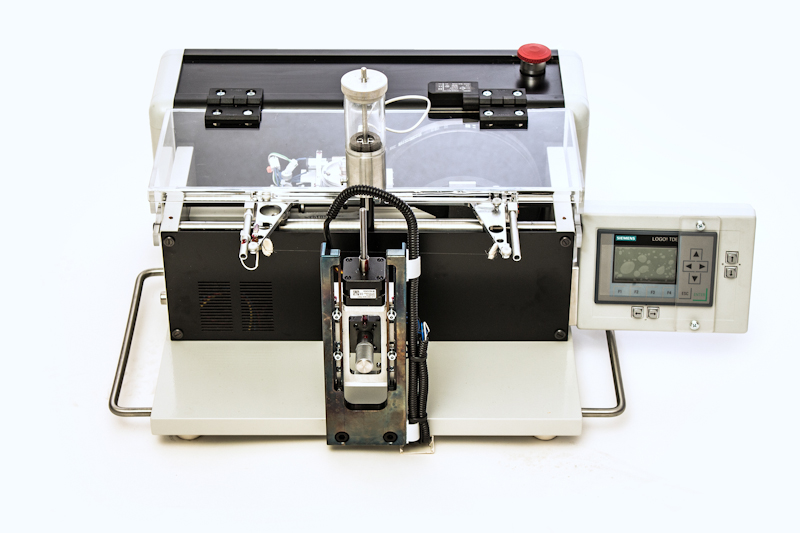

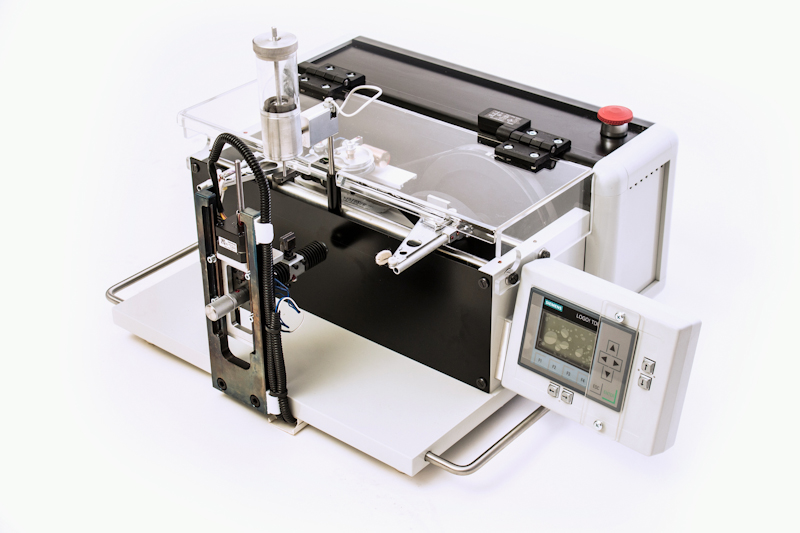

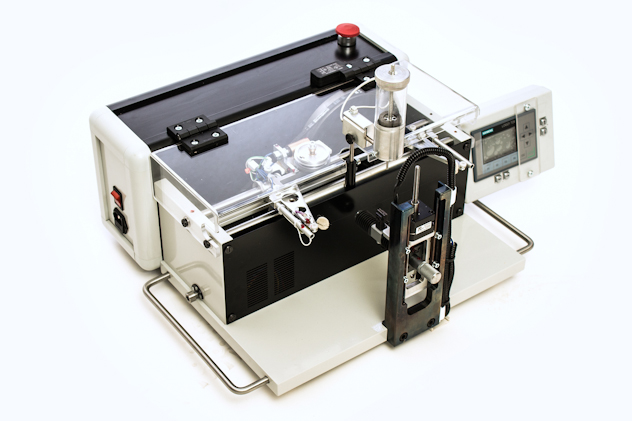

WS-25 High Precision Wire Saw with electronical sample support

Technical data:

Sample max. dimensions:

Power supply:

.

Tungsten wire diameter:

Diamond doted wire:

Wire oscillation frequency:

Weight:

Dimensions:

Sample max. dimensions:

Power supply:

.

Tungsten wire diameter:

Diamond doted wire:

Wire oscillation frequency:

Weight:

Dimensions:

The WS-25 wire saw has been developed to meet two important requirements: cutting should not introduce deformations or defects, and losses of material should be minimized. These two requirements have been met by the development of an improved cutting technique which utilizes the precision guidance of the wire and uniform application of an abrasive slurry. Saw is a semi-automatic machine and requires no supervision during its operation. Saw can be used for precision cutting of semiconductors, ferrites, metals, glasses as well as many other hard or brittle solids. Wire saw enables cutting of very thin slices (down to thickness of 10 µm) with smooth cut surfaces (surface roughness does not exceed 1µm). The WS-25 saw is particularly recommended for cutting materials where minimization of material losses and surface demands are important. Using the thinnest wire (20 µm diameter) and proper abrasive powder dimensions the material losses do not exceed 30 µm. Obtained slices are perfectly parallel, thus additional lapping is unnecessary. Cutting at any desired angle is possible due to the rotation of the sample holder. Use of the special accessories (goniometers, orientation devices) extends WS-25 saw's application in precision cutting of crystallographically oriented crystals.

Application:

In free abrassive cutting method, thin tungsten wire moistened with an oil or glycerine-suspended abrasive slurry is used, and the slurry is applied continouosly to cutting area. In abrassive method, diamond doted wire is used. Wire moves rapidly back and forth in an oscillatory motion. High cutting accuracy is guaranteed by the following features:

• Sample support is automatically moved up as wire cuts through material. Thanks to this solution wire guide posts are no longer needed, thus

they wear doesn't affect cutting quality and saw maintance is cheaper.

• Wire load on the sample is precisely controlled.

• To prevent wire wear, wire is fed continuously to the cutting area with electronically controlled motor.

Cutting speed depends mainly on the wire load, sample hardness, sample shape and for such materials as Ge, InSb,HgTe, GaS is approximately from 1 up to 3 cm2/h. WS-25 saw is equipped with a high precision horizontal sample carriage mechanism. Displacement of the sample by 30 mm with a deviation less than 0.002 mm is possible. Sample holder can rotate around the vertical axis and be fixed in any desired position. Saw is equipped with an automatic switch-off (AUTO-STOP) which turns off the saw when the cutting wire is torn, the cutting is completed, or the desired cutting depth is achieved. Saw is also equipped with a magnetically driven mixing device which batches the slurry. The mixing and batching procedure is automatically controlled by an electronic system, which enables adjustment of dropping frequency and drop formation time (dependent on the viscosity and density of the slurry). Electonically controlled support allows precise vertical positioning of sample during and before cutting. WS-25 is also fitted with safety switches, which turn the saw off when the cover is opened.

• Sample support is automatically moved up as wire cuts through material. Thanks to this solution wire guide posts are no longer needed, thus

they wear doesn't affect cutting quality and saw maintance is cheaper.

• Wire load on the sample is precisely controlled.

• To prevent wire wear, wire is fed continuously to the cutting area with electronically controlled motor.

Cutting speed depends mainly on the wire load, sample hardness, sample shape and for such materials as Ge, InSb,HgTe, GaS is approximately from 1 up to 3 cm2/h. WS-25 saw is equipped with a high precision horizontal sample carriage mechanism. Displacement of the sample by 30 mm with a deviation less than 0.002 mm is possible. Sample holder can rotate around the vertical axis and be fixed in any desired position. Saw is equipped with an automatic switch-off (AUTO-STOP) which turns off the saw when the cutting wire is torn, the cutting is completed, or the desired cutting depth is achieved. Saw is also equipped with a magnetically driven mixing device which batches the slurry. The mixing and batching procedure is automatically controlled by an electronic system, which enables adjustment of dropping frequency and drop formation time (dependent on the viscosity and density of the slurry). Electonically controlled support allows precise vertical positioning of sample during and before cutting. WS-25 is also fitted with safety switches, which turn the saw off when the cover is opened.

General Characteristics:

Thanks to inovative design WS-25 wire saw is first wire saw that can cut with free abresive method as well as with diamond doted wire. WS-25 is fitted with adjustable sample support with electronical vertical axis. Sample is automatically moved up during the cutting process. Wire frame stays at the same vertical position throught process. Vertical axis has 2 adjustments: manual, coarse and fine, electronical adjustment. Manual adjustment is used to set cuting range accordingly to sample size and mounted equipment. Fine regulation is used to precisely set sample position before cutting. Saw is equipped with new user interface, including display screen and 8 functional buttons. Inteface facilitates: adjusting cutting parameters, setting sample position and monitoring cutting process.

K.D. UNIPRESS

Providing laboratory equipment since 1990

High Pressure Physics Institute

Polish Academy of Science